Lilac Announces Successful Operations of Lithium Demonstration Plant in Argentina

OAKLAND, CA, UNITED STATES, May 14, 2025 /EINPresswire.com/ -- Lilac, a leading provider of direct lithium extraction (DLE) technology, today announced the successful operations of its lithium extraction demonstration plant in Jujuy, Argentina. The plant featured Lilac’s latest fourth generation ion exchange (IX) technology, achieving 91% lithium recovery from salar brine with a lithium grade of 300 mg/L and a 99.4% overall impurity rejection rate. The demonstration plant leveraged a lithium extraction module built with 100% off-the-shelf equipment, matching the commercial design with a vessel sized at approximately one-third commercial scale. This achievement marks a critical milestone in scaling up Lilac IX technology, demonstrating excellent lithium recovery, purity, and IX material cycle life throughout operations.

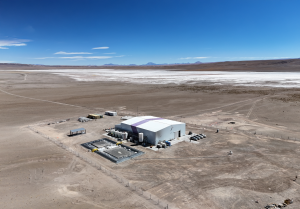

The plant highlights the capabilities of Lilac’s technology and team to deliver results under challenging field conditions with a system design that mirrors commercial scale. It operated continuously 24/7 in a remote desert location at 4,000 meters above sea level and leveraged the same controls and automation system planned for commercial deployment.

Key Performance Metrics:

• Lithium Recovery: 91%

• Overall Impurity Rejection: 99.4%

• Plant Throughput*: 42 tonnes LCE/year

• IX Vessel Size: ~1/3 of commercial scale

• Eluate Lithium Concentration from DLE**: 2,300 mg/L

* Equivalent throughput if run continuously for 1 year

** Raw eluate prior to any further downstream concentration or treatment

Lithium recovery at the Jujuy demonstration plant was stable, averaging 91% and exceeding the commercial plant design basis of 90%. The Lilac IX media delivered excellent selectivity of lithium over major cations such as sodium, magnesium, calcium, potassium, and boron. Notably, the Lilac IX process achieved 99.9% rejection of sodium, the primary impurity in the feed brine. The overall impurity rejection rate was 99.4%. Hatch was on-site to witness the operation of the demonstration plant and verified its performance.

The consistently high and stable eluate purity supports a cycle life estimate of over 4,000 IX media cycles on the Jujuy brine, which is consistent with the performance seen at mini-pilot scale.

“The success of our Jujuy demonstration plant is a major validation of Lilac’s technology and team,” said Raef Sully, chief executive officer of Lilac. “We’ve proven that our Gen 4 ion exchange technology can meet and exceed the plant design basis under real-world conditions. This milestone advances Lilac toward full commercial deployment and strengthens our ability to help producers bring new lithium projects online.”

About Lilac

Lilac exists to solve one problem: lithium supply. By engineering scalable lithium extraction technology, Lilac helps producers deliver lithium faster, cheaper, and cleaner. Our ion exchange technology is rooted in scientific precision and commercial know-how, unlocking lithium supply for global electrification. Our materials, engineering, and approach uniquely position us to develop commercial projects across a range of brine resources. We help lithium producers rapidly and responsibly scale production with versatile, cost-effective, and high-performance technology solutions. Learn more at lilacsolutions.com.

Elizabeth Pond

VP of Communications & Brand, Lilac Solutions

press@lilacsolutions.com

Visit us on social media:

LinkedIn

Distribution channels: Automotive Industry, Chemical Industry, Energy Industry, Mining Industry, Technology

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release